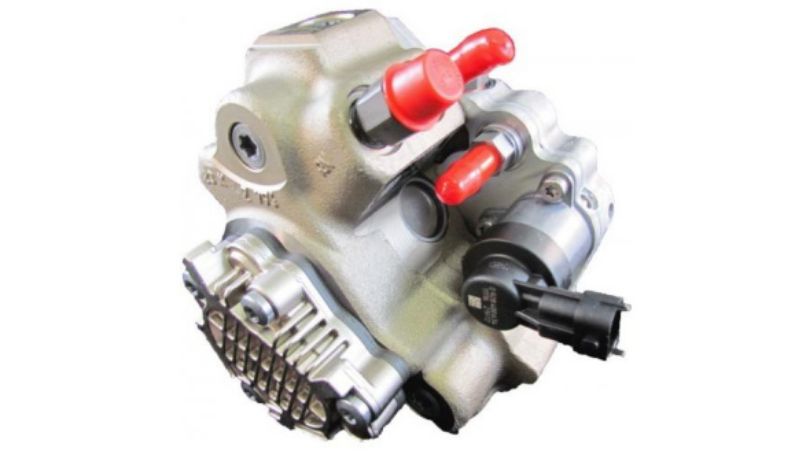

We all know the 2011-2016 LML Duramax features the CP4 injection pump which was supposed to be an "upgrade" over the CP3 units on the 01-10 Duramax trucks. This is certainly the opposite as it doesn't flow as well as the CP3 and the design can cause a catastrophic fuel system failure. When it does fail, it will send metal particulates throughout the entire fuel system and destroy injectors, rails, lines, etc.

Why?

The CP4 fails because it makes higher pressure without the same volume as the CP3 unit before it and this causes it to be less lubricated. Bad/dirty fuel also doesn't help the problem as it puts even more stress on the pump.

Usually, you'll have a good idea of your CP4 "grenading" as it will shut down (have a no start) and could throw codes such as P0087, P0088, P0191, or P128E. Some catch the problem soon enough to where the metal didn't enter the entire fuel system, but it's best not to chance it.

The easiest way to tell is to pull the fuel pressure regulator and inspect it. If there are excessive metal shavings, torn screens, or cracks, then it's a good bet the pump has failed.

Factory Fix For Failure:

GM recommends changing out the fuel injectors, fuel lines, rails, pump, return lines, filters, and in some cases the fuel tank. After that, you need to flush and clean all lines, tank, filter, and sender unit.

Things That Are Beneficial But Won't Prevent Failure Completely:

-A Fass or Airdog Lift pump:

Lift pumps will clean the fuel and take the air out before sending it to the injectors and pump. This along with a constant psi flow takes stress off the pump and provides clean fuel. The size of the pump doesn't matter so the 165gph pump would offer the same as the 95gph in terms of clean fuel to the pump.

-Exergy Fuel Saver's

Exergy released their "fuel system saver" pressure regulators a few years back to upgrade the factory fuel regulator.

The Exergy System Saver is a drop-in replacement of the factory Inlet Metering Valve. The System Saver gets its name from the job it’s meant for, saving the system. In a CP4 Failure with a Factory Metering Valve, the 80-micron Single-Layer Screen lets metal shavings and debris past, wreaking havoc on your Injectors. This leaves you with a costly repair bill.

In a CP4 Failure with an Exergy System Saver, the 25-micron Double-Layer Screen stops metal shavings and debris before they can get past. The 25-micron screen will clog much quicker as well as stop the metal, which closes the valve and shuts the truck down before any further damage can occur. This leaves you with just having to replace the injection pump. A much more economical stance for a minor upfront cost.

There have been a few instances of a System Saver being installed and consumers having an issue with not being able to meet desired rail pressure. This is not a fault of the System Saver, but a major indicator that the CP4 Injection Pump is worn out and near the end of its life. If this is the case, it’s time to think of a CP3 Conversion in the very near future.

Our friends at Under Dog Diesel with a nice install write-up!

How To Prevent CP4 Failure:

- CP3 Conversion Kit

There's one way to prevent the failure 100% with two kit options, and that's doing a CP3 swap. The CP3 Conversion kit & injection pump will not only add to your reliability, but you will also have more flow potential.

Kit Option #1:

Now custom tuning is required so this may not an option for some. This method is pretty straightforward as you replace the CP4 pump with the CP3 and install the conversion kit.

In terms of kits, the SDP kit is one of the best on the market and offers parts to allow you to delete the very leak-prone flare-nut connection that feeds the CP3.

Here's a link to the kit and we can add either the Exergy or S&S CP3 pump.

Option #2:

S&S Diesel has several kits and one that does not require tuning, so it's 50-state legal. This is popular for customers in the state of California and is emissions compliant.

In conclusion, there are several ways to help the fuel system out or fix it completely. The failure rate will vary depending on the source, but the national failure rate average is between 4-7% of all LML trucks on the road.

Hunter Holdridge- Injected Motorsports

Contributions: Hunter Rabourn- Underdog Diesel